Abstract

To evaluate the effect of sawdust (SD) and rice straw (RS) on yield of different strains of Pleurotus cystidiosus (PCYS1-5), various yield attributes were measured in the present experiment. Among them, the best effect had been observed in the case of PCYS2. The highest mycelial running rate was observed in PCYS-2 + SD (0.84 cm). The highest average number of fruiting body/packet was observed in the treatment PCYS-2 +SD (61.00), followed by PCYS-1 +SD (58.00), PCYS-2 +RS (58.00) and the lowest in the treatment PCYS-3 +RS (47.00). The highest biological yield was observed in PCYS-2 + SD (255.6 g) and the lowest in PCYS-1 + RS (193.7 g). PCYS-2 + SD also showed the highest biological (255.6 g) and economic yield (188.3 g), the dry yield (25.02 g) and the highest biological efficiency of (85.20%). However, the highest cost benefit ratio was calculated in treatment PCYS-3 + RS (7.69) and the lowest cost benefit ratio 6.34 was calculated for PCYS-3 + SD and PCYS-4 + RS. Thus, saw dust stands out as the better substrate and the PCYS-2 as the best strain in the present experiment.

Keywords

Biological yield, Cost benefit ratio, Economic yield, Mycelium running rate

Introduction

The genus Pleurotus, belonging to the family Tricholomataceae, is the second most cultivated culinary mushroom, following Agaricusbisporus, in the world [1]. Cultivation of Pleurotus in Asian countries surpasses that of other mushrooms and there remains ever increasing demand for high yield for the sake of low cost [2]. Thus, the search for low-cost techniques and technologies have received lofty concern in mushroom research and development academia and industries. In Bangladesh, rice straw and saw dust are easily available substrates for mushroom cultivation. As composition, quality, quantity, and ratio of different substrates and impact the production of different mushroom species highly, a standard protocol for cultivation of P. cystidiosus, especially for the Bangladeshi mushroom growers, would benefit mushroom industries and associated pharma and nutraceutical industries as well as national economy immensely [3,4]. In fact, P. cystidiosus is among the least reported mushroom species in regard to yield and nutrition-based information [5]. Though other species of Pleurotus have received high attention in regard of cultivation in Bangladeshi perspective, P. cystidiosus has received the opposite [6]. Thus, the present study had been aimed at introducing rice straw- and saw dust-based a novel, low-cost yet high yielding technique for producing different strains of P. cystidiosus in Bangladesh perspective.

Materials and Methods

Location of the experiment

The experiment had been carried out at the Mushroom Development Institute, Savar, Dhaka, Bangladesh from June to December, 2019.

Experiments and treatments

The experiment was laid out in single factor Completely Randomized Design (CRD).Ten different treatments with three/4 replications of each strain were conducted to achieve the desired objectives. The experiments were as follows: P. cystidiosus-1 + sawdust (PCYS-1 + SD), P. cystidiosus-2 + sawdust (PCYS-2 + SD), P. cystidiosus-3 + sawdust (PCYS-3 + SD), P. cystidiosus-4 + sawdust (PCYS-4 + SD), P. cystidiosus-5 + sawdust (PCYS-5 + SD), P. cystidiosus-1 + rice straw (PCYS-1 + RS), P. cystidiosus-2 + rice straw (PCYS-2 + RS), P. cystidiosus-3 + rice straw (PCYS-3 + RS), P. cystidiosus-4 + rice straw (PCYS-4 + RS), P. cystidiosus-5 + rice straw (PCYS-5 + RS).

Preparation of packets

Preparation of spawn packets: Sawdust spawn packets of 500 g size were prepared, inoculated, and incubated following the procedure that developed and explained by Sarker et al. [7].

Preparation of substrate: The substrate was prepared by MDI developed pasteurization method. At first the straw was chopped to 4-5 cm length. Twenty kg rice straw with 17 liter water were mixed together. Then the mixture was poured (3-4 kg/ bag) in net’s bag. The bags were kept in a rack of MDI developed sterilization cum chamber at 60-70°C for one hour. Afterwards the bags were kept in same place for 16-22 hours to get cool slowly. After about 16-22 hours the prepared straw mixture was ready for preparation of spawn packets. The moisture level of the substrate was 65%.

Preparation of spawn packets: Pasteurized substrate and sawdust based spawn packet were mixed thoroughly without supplementation according to treatments. The polypropylene bags were filled with the mixture i.e., substrate mixture was poured into polypropylene bags according to spawn rate. Then their mouths were plugged by inserting absorbent cotton with the help of plastic neck. The neck of the bag was prepared by using a heat resistant plastic pipe. The prepared packets were incubated in culture house at 25-30°C.Thorough spawning of the substrate was also followed in which the spawn was thoroughly mixed with the wet substrate before bagging.

Experimental condition: The packets were kept in a dark room at 25°C for incubation. When colonization of mycelium was completed, the spawn packets were taken to culture house and were opened by ‘D’ shaped cut on the shoulder and removed the sheet. The relative humidity and temperature of the culture house were maintained at 80-90% and 20-25°C respectively by spraying water. Water was sprayed 4-5 times per day. Diffused light, about 200 lux and proper ventilation in culture house were maintained. After harvesting of mushroom, the residues were removed from the packet and temperature and relative humidity were maintained as before. The yield was obtained from single, double and third flush in the harvest period. Yield in g/packet was recorded by weighing all the fruiting bodies in a packet after removing the lower dirty portion. Biological efficiency was calculated according to the formula:

Preparation of master mother culture: To prepare mother culture of the test mushroom strain sawdust and wheat bran were mixed together at 2:1 (v/v) and supplemented with CaCO3 at 0.2% (w/w) of the mixture. The moisture level of the mixed substrate was maintained at 65% with tap water. The substrate was poured into polypropylene bags (7" × 10") at 300 g/bag. The substrate in bags was sterilized in an autoclave for 1 h at 121°C under 1.1 kg/cm2 pressures and allowed to cool for 24 h. Pure cultures of Cid-1 strains were grown on potato dextrose agar (PDA) following hyphal tip method. A piece of the PDA culture of test strain containing mycelium was placed aseptically in the opening of the mother culture packets. The inoculated packets were placed on a rack in the laboratory at 22 ± 2°C for incubation. The substrate of the mother culture was covered by whitish mycelium within 15-20 days after inoculation. The fully colonized packets were used as master mother for inoculation of mother culture.

Preparation of mother culture (paddy): To prepare mother culture of the test mushroom paddy grains were used as media of mother culture. At first grains collected which were free from diseases and not broken, old, and insect damaged. The grains were thoroughly washed in sufficient water three to four times to remove soil debris, straw particles and undesirable seed of grasses, weeds, etc. Washed grains were then soaked in sufficient water for 2-3 hours and boiled in a container for 25-45 minutes till the skin started to crack. Excess water from the boiled grains was removed by stirring and heating. Then the grains were thoroughly mixed with calcium carbonate at 0.2% so that the pH of the grains was around 7.0 to 7.8. This mixing was done in the same container after wearing gloves. The substrate was poured into polypropylene bags (9" × 12") at 400-450 g/bag. The neck of the bags was heat resistant plastic and the neck was plugged with cotton wool, covered with paper piece and then tied together by a rubber band. The substrate in bags was sterilized in an autoclave for 2 h at 121°C under 1.1 kg / cm2 pressures and allowed to cool for 24 h. Then the master mother was poured aseptically at 10% in the opening of paddy grain containing mother culture packets and substrate grain was covered by whitish mycelium within 10-15 days after inoculation. The fully colonized packets were used as mother culture for spawning.

Preparation of substrate: The substrate was prepared by MDI developed pasteurization method. At first the straw was chopped to 4-5 cm length. Ten kg sawdust and ten kg rice straw with 17 liter water were mixed separately. Then the mixture was poured (3-4 kg/ bag) in net’s bag. The bags were kept in a rack of MDI developed sterilization cum chamber at 60-70°C for one hour. Afterwards the bags were kept in the same place for 16-22 hours to get cool slowly. After about 16-22 hours the prepared straw and sawdust was ready for preparation of spawn packets. The moisture level of the substrate was 65%.

Preparation of spawn packets: The polypropylene bags of "9 × 12" size were filled with pasteurized substrates and mother culture according to treatments. Pasteurized sawdust, rice straw and mother culture of different strains mixed thoroughly separately without supplementation i.e., through spawning method was done. Then their mouths were plugged by inserting absorbent cotton with the help of plastic neck. The neck of the bag was prepared by using a heat resistant plastic pipe. The prepared packets were incubated in culture house at 20-25°C. Thorough spawning of the substrate was also followed in which the spawn was thoroughly mixed with the wet substrate before bagging.

Spawn packets using sawdust and rice straw were prepared separately with different spawn preparing substrate; sawdust supplemented with wheat bran and CaCO3 (1 g per packet) was added. The measured materials were taken in a plastic bowl and mixed thoroughly by hand and moisture was increased by adding water. Moisture was measured by using the moisture meter and adjusted the moisture content at 50%. 500 g of the mixed substrates were filled into each 9×12 7×10 inch polypropylene bag. The filled polypropylene bags were prepared by using bamboo neck and plugged the neck with cotton and covered with brown paper placing rubber band to hold it tightly in place.

Sterilization, inoculation, and mycelium running in spawn packets: The packets had been sterilized for about 12 hr and kept for cooling. After cooling, 5 g mother spawn were inoculated into the packets in the laminar airflow cabinet and were kept at 20-22°C temperature until the packets become white with the mushroom mycelium. After completion of the mycelium running the rubber band, brown paper, cotton plug and bamboo neck of the mouth of spawn packet were removed and the mouth was wrapped tightly with rubber band. Then these spawn packets were transferred to the culture house.

Cultivation of spawn packet: The two upper ends of the packets (opposite to each other) had been cut in "D" shape with a blade and opened by removing the plastic sheet. The opened surface of substrate was scraped slightly with a teaspoon to remove the thin whitish mycelial layer. Then the spawn packets were soaked in water for 15 minutes and invested to remove excess water for another 15 minutes. The packets of each type were placed separately on the floor of the culture room and covered with newspaper. The moisture of the culture room was maintained 80-85% relative humidity by spraying water 3 times a day. The light around 300-500 lux and ventilation of culture house was maintained uniformly. The temperature of culture house was maintained 22°C to 25°C. The first primordia appeared 2-4 days after scribing depending upon the type of substrate. The harvesting time also varied depending upon the type of substrate.

Collection of produced mushrooms: Usually, the Oyster mushrooms (Pleurotus)matured within 2-3 days after primordia initiation. The matured fruiting body was identified by curial margin of the cap. Mushrooms were harvested by twisting to uproot from the base.

Data collection

Days required for completing mycelium running: Days required from inoculation to completion of mycelium running were measured.

Average number of fruiting body/packet: Number of well-developed fruiting body was recorded. Dry and pinheaded fruiting bodies were discarded but tiny fruiting bodies were included in counting.

Average weight of individual fruiting body/packet: Average weight of individual fruiting body was calculated by dividing the total weight of fruiting body per packet by the total number of fruiting body per packet.

Biological yield (g): Biological yield per 500 g packet was measured by weighing the whole cluster of fruiting body without removing the lower hard and dirty portion.

Economic yield: Economic yield per 500 g packet was recorded by weighing all the fruiting bodies in a packet after removing the lower hard and dirty portion.

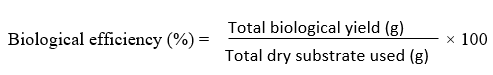

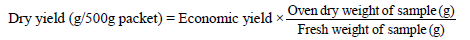

Dry yield: About 50 g of randomly selected mushroom sample was taken in a paper envelope and was weighed correctly. The mushroom was oven dried at 72°C temperature for 24 hours and weighed again. The weight of the blank envelop was subtracted from both the initial weight. The dry yield was calculated using the following formula [7]:

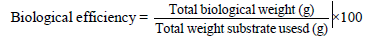

Biological efficiency: Biological efficiency was determined by the following formula [8]:

Cost benefit ratio: The cost benefit ratio for different low cost substrate were computed based on present market price of mushroom and cost of different inputs in the markets [7].

Drying of mushrooms: The collected fruiting bodies of the mushroom are transferred to the laboratory. Therefore, data are collected on different parameters. After collection of the data the fruiting bodies are dried in the sun separately treatment wise. During the time of drying, the stipe and the pileus had been separated for better drying.

Results and Discussion

This is the novel study on P. cystidiosus and there is scarcity of information on the effect of rice straw and saw dust on P. cystidiosus cultivation and thus the current findings could not be compared with any other study.

Mycelium Running Rate (cm/day)

The mycelium running rate per day (MRR) for each type of substrates was measured after the mycelium colony crossed the shoulder of the packet. The linear length was measured at different places of packet. The mycelium running rate in spawn packet was found to be differed due to different substrates used. The highest running rate was observed in PCYS-2 + SD (0.84 cm) and the lowest running rate of mycelium was observed in PCYS-3 + RS (0.53 cm). The other treatments varied significantly over control (Table 1). The lowest mycelial growth (0.22 cm/day) was observed in Pcys-3.

|

Treatments |

Mycelium running rate in spawn packet (cm) |

Time from stimulation to primordial initiation (days) |

Time from primordial Initiation to harvest (days) |

|

PCYS-1 +SD |

0.58e |

8.38a |

4.21a |

|

PCYS-2 +SD |

0.84c |

7.50b |

3.13b |

|

PCYS-3 +SD |

0.69g |

7.38b |

3.39b |

|

PCYS-4 +SD |

0.72f |

7.15b |

4.04b |

|

PCYS-5 +SD |

0.65e |

7.23b |

5.17c |

|

PCYS-1 +RS |

0.61a |

7.93b |

4.12a |

|

PCYS-2 +RS |

0.70c |

7.67c |

3.31a |

|

PCYS-3 +RS |

0.53d |

7.05b |

4.01a |

|

PCYS-4 +RS |

0.73c |

6.91b |

4.33a |

|

PCYS-5 +RS |

0.62b |

7.16b |

4.72c |

|

CV (%) |

0.63a |

5.18b |

3.09b |

|

Level of significance |

** |

** |

** |

|

LSD (0.05) |

0.028 |

1.169 |

0.358 |

|

Means sharing common superscripts are significantly different at 1% or 5% level of confidence. Here, NS stands for not significant; * for significant at 5% level; ** for significant at 1% level; PCYS+ SD: Pleurotuscystidiosus + Sawdust; PCYS+ RS : Pleurotuscystidiosus + Rice Straw. |

|||

Time from stimulation to primordia initiation (Days)

The time from stimulation to primordia initiation ranged from 5.1 days to 7.1 days. The highest time from stimulation to primordia initiation was observed in PCYS-1 + SD (8.38 days). The other treatments varied significantly in terms of time from stimulation to primordia initiation (Table 1). But the lowest time from stimulation to primordia initiation was in the treatment PCYS-4 + RS (6.91 days). No previous finding is available so that the time from stimulation to primordia initiation (Days) can be compared with that finding.

Time from primordia initiation to harvest (days)

The lowest time from primordia initiation to harvest was in the treatment PCYS-2 + SD (3.13 days) and the highest time from primordia initiation to harvest was observed in the treatment PCYS-5 + SD (5.17days) followed by PCYS-5 + RS (4.72 days), PCYS-4 +RS (4.33 days). The other treatments were statistically similar (Table 1). The result of the present findings can’t be compared with previous findings as no data is available in this regard.

Average number of primordia: The highest average number of primordia/packet was observed in the treatment PCYS-2 + RS (73.25) followed by PCYS-2 + SD, PCYS-1 + RS, PCYS-1 +SD, PCYS-5 + RS, PCYS-3 + RS and the lowest average number of primordia/packet was in the treatment PCYS-4 + SD (59.00). The other treatments varied significantly over control (Table 2). The result of the present findings can’t be compared with previous findings as no data is available in this regard.

|

Treatments |

Average no. of primordial /packet |

Average no. of fruiting body/packet |

Average weight of individual fruiting body (g) |

|

PCYS-1 +SD |

69.00a |

58.00b |

3.69a |

|

PCYS-2 +SD |

70.67a |

61.00a |

3.57b |

|

PCYS-3 +SD |

66.00b |

53.00c |

3.70b |

|

PCYS-4 +SD |

59.00c |

51.00c |

3.29c |

|

PCYS-5 +SD |

62.33b |

48.00b |

3.13b |

|

PCYS-1 +RS |

70.12a |

53.00a |

3.33d |

|

PCYS-2 +RS |

73.25b |

58.00b |

3.29a |

|

PCYS-3 +RS |

61.62c |

47.00a |

3.41b |

|

PCYS-4 +RS |

65.03b |

55.00b |

3.23b |

|

PCYS-5 +RS |

67.21b |

51.00c |

3.52a |

|

CV (%) |

1.51 |

1.85 |

0.95 |

|

Level of significance |

** |

** |

** |

|

LSD (0.05) |

2.25 |

2.65 |

0.091 |

|

Means sharing common superscripts are significantly different at 1% or 5% level of confidence. Here, NS stands for not significant; * for significant at 5% level; ** for significant at 1% level; PCYS+ SD: Pleurotuscystidiosus + Sawdust; PCYS+ RS : Pleurotuscystidiosus + Rice Straw. |

|||

Average number of fruiting body: The highest average number of fruiting body/packet was observed in the treatment PCYS-2 +SD (61.00), followed by PCYS-1 +SD (58.00), PCYS-2 +RS (58.00) and the lowest average number of fruiting body/packet was in the treatment PCYS-3 +RS (47.00). The other treatments were statistically and significantly varied over control in terms of average number of primordia/packet (Table 2). The result of the present findings keeps in with the findings of previous scientist Howlader et al. (2011) who reported the number of effective fruiting bodies was the highest (37.25) in pcys-1.

Average weight of individual fruiting body (g): Supplementation of rice straw and sawdust had a great effect on average weight of individual fruiting body. The average weight of individual fruiting body in different treatment ranged from 3.06 g to 3.69 g. The highest average weight of individual fruiting body was observed in the treatment PCYS-3 +SD (3.70 g) and the lowest average weight of individual fruiting body was in the treatment PCYS-5 +SD (3.13 g). The other treatments varied significantly over control in terms of average weight of individual fruiting body (Table 2).

Biological Yield (g): The supplementation of rice straw and sawdust had a great effect on biological yield. The highest biological yield was counted under treatment PCYS-2 + SD (255.6 g) and the lowest biological yield was counted under PCYS-1 + RS (193.7 g). The other treatments varied significantly as compared with control in terms of biological yield (Table 3). The result of the present study corroborates with the study of Howlader et al. [9] who reported the highest biological yield was 196.3 g/packet obtained from Pcys-1, which followed by Pcys-2, Pcys-4 and Pcys-5. The lowest biological yields was observed in Pcys-6.

|

Treatments |

Biological yield (g) |

Economic yield (g) |

Dry yield (g) |

Biological efficiency (%) |

Cost benefit ratio |

|

PCYS-1 + SD |

217.3a |

212.3a |

21.15a |

72.43a |

7.29a |

|

PCYS-2 + SD |

255.6a |

250.6a |

25.02b |

85.20b |

7.58a |

|

PCYS-3 + SD |

239.2a |

233.2a |

23.20a |

79.73a |

6.34b |

|

PCYS-4 + SD |

194.7a |

189.0a |

18.85c |

64.9a |

7.32a |

|

PCYS-5 + SD |

209.4b |

204.4b |

20.40a |

69.80a |

6.67b |

|

PCYS-1 + RS |

193.7bc |

188.3b |

18.75b |

64.26a |

6.72b |

|

PCYS-2 + RS |

234.5a |

229.2c |

22.86a |

78.15a |

7.23c |

|

PCYS-3 + RS |

245.3c |

240.5c |

24.01b |

81.91a |

7.69c |

|

PCYS-4 + RS |

199.4b |

196.3a |

19.45c |

66.55a |

6.34b |

|

PCYS-5 + RS |

201.9a |

196.6b |

19.54b |

66.89a |

7.02a |

|

CV (%) |

1.51 |

1.85 |

|

0.95 |

0.45 |

|

Level of significance |

** |

** |

|

** |

** |

|

LSD (0.05) |

2.25 |

2.65 |

|

0.091 |

0.089 |

|

Means sharing common superscripts are significantly different at 1% or 5% level of confidence. Here, NS stands for not significant; * for significant at 5% level; ** for significant at 1% level; PCYS+ SD: Pleurotuscystidiosus + Sawdust; PCYS+ RS : Pleurotuscystidiosus + Rice Straw. |

|||||

Economic Yield (g): The highest economic yield was recorded under treatment PCYS-2 + SD (255.6 g) and the lowest economic yield was counted under PCYS-1 + RSD (188.3 g). The other treatments varied significantly over control (Table 3). The lowest biological yields were observed in Pcys-6.

Dry yield: The dry yield of mushroom was maximum under the treatment PCYS-2 + SD (25.02 g) and the lowest dry yield was counted under PCYS-1 + RS (18.75 g). The other treatments varied significantly over control (Table 3). The result of the present findings can’t be compared with previous findings as no data is available in this regard.

Biological efficiency: The highest biological efficiency of 85.20% was calculated in treatment PCYS-2 + SD and the lowest biological efficiency of 64.26% was calculated from PCYS-1 + RS (Table 3). The other treatments varied significantly over control.

Cost benefit ratio: The highest cost benefit ratio was calculated in treatment PCYS-3 + RS (7.69) and the lowest cost benefit ratio 6.34 was calculated from PCYS-3 + SD and PCYS-4 + RS combinedly. The other treatments differed significantly in terms of cost benefit ratio (Table 3). As no such studies have been performed ever before, comparative discussion entailing current results cannot be performed.

Conclusion

Between rice straw and sawdust, saw dust had been observed as the better substrate for yield and yield attributes of P. cystidiosus. Among the five strains of P. cystidiosus (PCYS1 – 5) under the present experiment, the PCYS2 (PCYS-2 + SD) had been observed as the best yield providing. Thus, incorporation of saw dust (SD) for better production of P. cystidiosus seems prominent.

References

2. Mane VP, Patil SS, Syed AA, Baig MM. Bioconversion of low quality lignocellulosic agricultural waste into edible protein by Pleurotus sajor-caju (Fr.) Singer. Journal of Zhejiang University Science B. 2007 Sep;8:745-51.

3. Rahman MA, Al Masud A, Lira NY, Shakil S. Proximate analysis, phtochemical screening and antioxidant activity of different strains of Ganoderma lucidum (Reishi mushroom). Open Journal of Biological Sciences. 2020 Jun 11;5(1):024-7.

4. Rahman MA, Al Masud A, Lira NY, Shakil S. Proximate Analysis, Phtochemical Screening and Antioxidant Activity of Different Strains of Auriculariaauricula-judae (Ear Mushroom). International Journal of Traditional and Complementary Medicine.2020;5(29):7-17.

5. Hoa HT, Wang CL. The effects of temperature and nutritional conditions on mycelium growth of two oyster mushrooms (Pleurotus ostreatus and Pleurotus cystidiosus). Mycobiology. 2015 Mar 1;43(1):14-23.

6. Rahman A, Hossan T, Amin SR, Rahman KA, KHAN M, Khalil I. Antimicrobial activity of Pleurotus ostreatus (Jacquin ex Fr.) Kummer Upon Human Pathogenic Bacteria. Bangladesh J. Mushroom. 2009;3(1):9-13.

7. Sarker NC, Hossain MM, Sultana N, Mian IH, Karim AJ, Amin SR. Performance of different substrates on the growth and yield of Pleurotus ostreatus (Jacquin ex Fr.) Kummer. Bangladesh J. Mushroom. 2007;1(2):9-20.

8. Ahmed SA, Kadam JA, Mane VP, Patil SS, Baig MM. Biological efficiency and nutritional contents of Pleurotus florida (Mont.) Singer cultivated on different agro-wastes. Nature and Science. 2009;7(1):44-8.

9. Howlader KR, Khan AS, Moonmoon M, Kakon AJ, Ahmed S, Sarker NC. Performance of different strains of Pleurotus cystidiosus under Bangladesh condition. Bangladesh J Mushroom. 2011;5(1):49-54.